Welcome to Zhangjiagang Gangying Industry!

Working hours:Mon - Sat 8.00 - 18.00

Call Us:+86-15951181288

Products

Bi-Component Fiber Production Line

Category:

Product Parameters

Specifications of Acrylic Fiber

Denier Size: 30Den to 450Den

Bi-Component fiber, also known as composite fiber, is formed by composite spinning holes at the same time. The common structural forms are: sheath core type, side by side, island type, and orange type.

The more common two-component hot-melt bonding fibers are ES fibers (PP/PE composite fibers). After the ES fiber is heat-treated, a part of the skin layer is melted to bond, and the rest remains in a fiber state, and at the same time, it has a small heat shrinkage rate, and a nonwoven fabric molded body without a binder can be formed. Non-woven fabrics with different effects can be obtained by selecting different heat treatment methods.

For example: hot air bonding type → fluffy non-woven fabric

Hot rolled adhesive type → high strength non-woven fabric

The ES fiber series has a wide range of processing suitability, and ES fibers can be used in all major nonwoven processing methods.

For example: hot rolled (CATENDER) hot air type (THROUGH-AIR), needled type (NEEDLE PUNCH), wet type (WET LAID), air laid type (AIR-LAID), spunlaced (SPUNLACE).

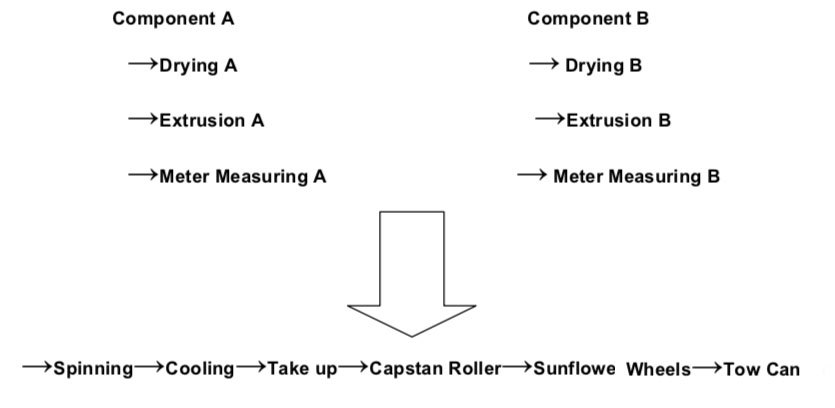

Spinning Line:

Finishing Line:

Creel Stand→Furl Stand→Guiding Frame→Dip Oil Bath→First Drafter→Draw Bath→Second Drafter→Steam Heated Beam→Third Drafter→Stacker→Crimper→Belt Conveyor→Spreader→Relaxing Oven→Tension Device→Cutter Device→Fiber Conveyor→Baler

Key words:

SPINNING LINE FINISHING LINE

Related Products

Get a Free Product Quote

We will contact you within one working day. Please pay attention to your email.

苏公网安备32058202012045号

苏公网安备32058202012045号